| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : ABB

Model Number : IRB 660-180/3.15

Place of Origin : China

MOQ : 1pcs

Price : Negotiation

Payment Terms : L/C,T/T

Delivery Time : 5-12WEEKS

Packaging Details : Original package

Type : IRB 660-180/3.15

Payload : 180kg

Reach : 3.15m

Weight : 1650 Kg

Axes : 4

Mounting : Floor

Accuracy : 0.23mm

The Abb Robot Arm has a high-speed design that allows it to quickly and accurately perform a wide range of tasks. With a maximum speed of 3.25 meters per second, this robotic arm can move quickly and efficiently, making it perfect for applications where speed is important.

In addition to its high-speed capabilities, the Abb Robot Arm also features advanced motion control technology that allows it to move with precision and accuracy. This technology allows the robotic arm to perform complex movements and tasks with ease, making it a versatile and reliable choice for any industrial application.

The Abb Robot Arm is also equipped with a user-friendly programming interface that makes it easy to set up and operate. The interface allows users to quickly create and modify programs, making it simple to adapt the robotic arm to changing production needs.

Overall, the Abb Robot Arm is a powerful and versatile tool that can help automate a wide range of industrial processes. Whether you need a high-speed robotic arm for palletizing, depalletizing, material handling, or assembly tasks, the Abb Robot Arm is an excellent choice.

✅ High Speed & Efficiency

Optimized for fast palletizing cycles, outperforming competitors in speed.

Can handle 4 feed conveyors, 2 pallet stacks, 1 slip-sheet stack, and 4 stacking discharge lines simultaneously .

✅ Precision & Reliability

±0.03 mm repeatability ensures consistent stacking quality .

ABB’s PickMaster software simplifies programming for quick setup .

✅ Durability & Flexibility

IP67-rated for harsh industrial environments .

Modular design allows integration into various production lines .

Advantage

| Service | We supply 3d model, foundation and flange dimensions of related robot. Supply training video to fresh customer. The video include of how to mastering,how to connect the cable,how to programming and so on. If you have any problem, call us anytime or sent email to us. |

| Robot Maintains | The robot we suggest maintains every one year or 10000 hours. the main job is exchange oil, fans,UPS and so on. If the robot working in terrible environment, just like low temperature or wet environment. So such case we suggest half year or 5000 hours to do maintains. |

| Warranty | 1 Year |

lace of origin: China

Brand Name: ABB

Model Number: IRB 660-180/3.15

| Type:IRB 660-180/3.15 | Weight: 1650 kg |

| Reach: 3.15m | Axis: 4 |

| Protection Rating: IP67 | Payload::180kg |

| Mounting Position: Floor | Position Repeatability:0.23mm |

Specification

| Robot model | Handling Capacity(KG) | Reach(M) |

| IRB 660-180/3.15 | 180 kg | 3.15 m |

| IRB 660-250/3.15 | 250 kg | 3.15 m |

Our product technical support and services for the ABB Robot Arm include:

- Online documentation and manuals

- Technical support hotline

- On-site support and maintenance services

- Spare parts and replacement components

- Training and education programs for operators and technicians

Product Packaging:

Shipping:

FAQ:

*Q:Why are we?

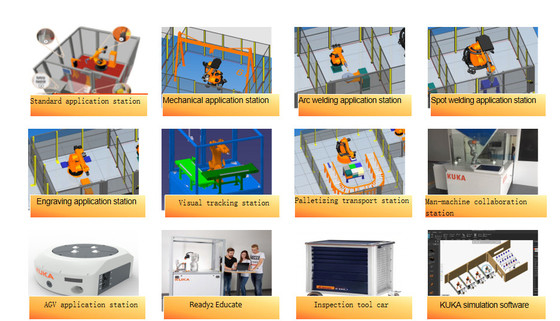

A:Our company works robot industry over fifteen years. Programming robot inclusive KUKA ,ABB,YASKAWA,FANUC,ESTUN(Chinese ROBOT ),EFORT(Chinese robot). the business involved simulation,programming,service after warranty period.

*Q:How about our service concept?

A:We keep on phone open all day. Stand in customer view to provide rationalization solution and robot selection.

*Q:What products can we offer?

A:robot, energy supply for robot, linear for robot. Training for robot. Gripper for handling.

*Q:Why you purchase from us?

A:You don’t worry about after-sales problem to cooperation with us.

About us

Companies in the "customer first, quality first, the user first" purpose, we will as always Warm and sincere service for all users, friends and customers, create brilliant tomorrow. Our main customers are Baosteel, INO,Volkswagen,Geely and so on. Over fifteen years experience in the robot industry. Our engineers can design solution,simulation,program and troubleshooting. So if you have any issue of robot. Call us any time. We will try our best to solve the problem. The other advantage is after-sales service,we have robot spare parts in stockroom. We can response promptly to help you resolve robot fault. We also have robot training. The course include programming, electric, mechanic and expert programming. So welcome to join our college.

|

|

Palletizing Machine 4Axis IRB 660 Quickly Accurately Perform Tasks Images |